We Say

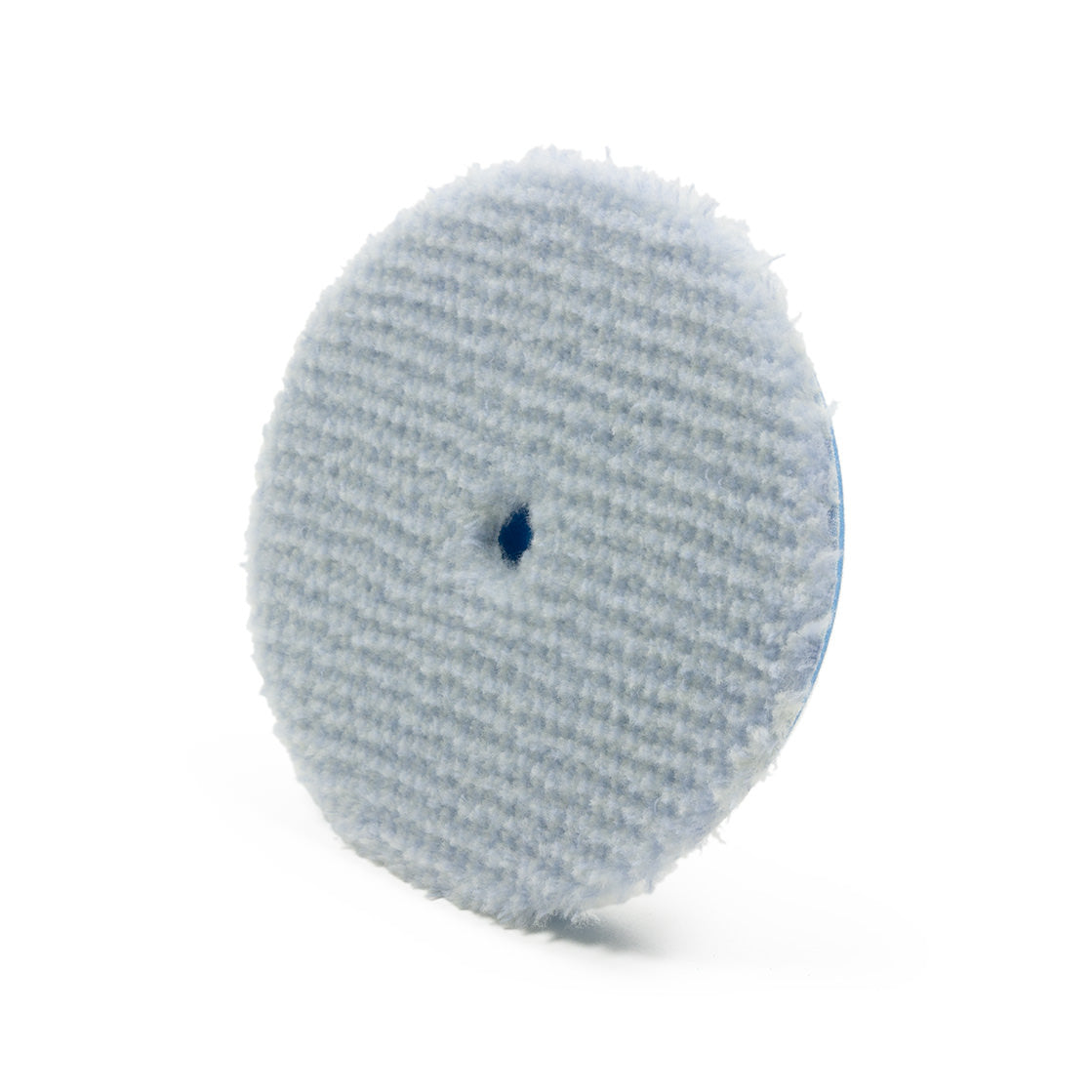

Natural wool fibres have been used as a polishing medium for automotive paint since the 1950s, mostly in the form of bulky dish-style pads designed to be used with traditional rotary polishers. Although it has been proven that such pads offer up to 30% more cut than their polyurethane foams counterparts, they are typically too heavy to be used on modern dual action polishers. However, in recent years, new methods of construction developed in Asia and Europe have resulted in the production of a new breed of ultra-thin wool pads with much lower rotational masses, meaning they can be used on dual action machines without causing any issues. In line with this, the RUPES BigFoot Coarse Wool Polishing Pad brings the awesome cutting power of wool to the RUPES line up of pads for the very first time. It is engineered specifically for fast defect removal on all paint types using the long-throw free-spinning and short-throw gear-driven dual action polishers in the BigFoot range, and offers a number of distinct advantages in otherwise troublesome situations. Firstly, compared to its foam- and microfibre-based equivalents, the RUPES BigFoot Coarse Wool Polishing Pad has a lower surface area, which means it suffers less drag on sticky paint types and makes polishing them less of a chore. Secondly, compared to the RUPES BigFoot Coarse Microfiber Polishing Pad, the RUPES BigFoot Coarse Wool Polishing Pad absorbs significantly less waste material as surfaces are compounded, which makes it much better suited for use on high yield surfaces such as OEM gelcoats.

Key Features

Cut Level9/10(Compared To Others)

Flexibility6/10(Compared To Others)

WashableYes(Hand Or Machine)

Description

The RUPES BigFoot Coarse Wool Polishing Pad is engineered specifically for compounding modern paint systems with long-throw free-spinning dual action polishers and short-throw gear-driven dual action polishers. It comprises an Asian-style construction that combines two natural wool fibres of differing lengths and densities with a backing layer of firm thermally reticulated foam. The inclusion of this supporting foam layer helps to transfer kinetic energy from the polisher to the work surface more efficiently, thus maximising cutting power. The end result is a pad that offers the high cutting performance of a traditional wool pad and the ease of use of a normal foam pad. Polishing efficiency is improved because the natural wool fibres correct deep scratches and swirl marks up to 30% faster than normal foam polishing pads, while safety is also improved because wool naturally absorbs much of the heat generated during the polishing process. Moreover, the use of the two different natural wool fibres creates a dual density surface that is visibly patterned. More than just an aesthetic detail, this configuration provides a better balance of cutting power and finishing ability compared to traditional wool pads. The RUPES BigFoot Coarse Wool Polishing Pad also features a centering hole and a durable hook and loop backing specifically designed to be able to withstand the high lateral forces generated by long-throw dual action polishers. The RUPES BigFoot Coarse Wool Polishing Pad is currently available in three different sizes.

Specification

| Compatible Backing Plate | ? 75 mm (90 mm)||? 125 mm (145 mm)||? 150 mm (170 mm) |

|---|---|

| Construction | Wool and flexible polyurethane foam |

| Cut Level | |

| Flexibility | |

| Foam Structure | Open cell |

| Promo Offer | BUY 3 OR MORE SAVE 5% |

| Suitable For Hard Paints | Yes |

| Suitable For Intermediate Paints | Yes |

| Suitable For Soft Paints | No |

| Washable | Yes (hand or machine) |

How To Use

General usage notes: (i) always select the least aggressive pad you think you will need to achieve the desired result, and step up one grade at a time if more cut is required (ii) always ensure that you centre each pad properly on the backing plate (this can take several attempts to get right, but is vital if the machine is to remain perfectly balanced during use); (iii) always use an appropriate sized pad for the backing plate you are using (the pad should always protrude past the edge of the backing plate, never the other way around); (iv) always prime a new pad by spreading a thin layer of product over it using a RUPES BigFoot Claw Pad Tool and running it stationary on the paint for 15 seconds at low speed; (v) always ensure that spent polish residue on the face of the pad is cleaned off regularly during use using either a compressed air gun or a RUPES BigFoot Claw Pad Tool (failure to follow this advice can lead to micromarring of the finish, so don't be lazy!); (vi) after use, soak each pad in a bucket of PB Snappy Clean Boost solution for 15 minutes and then rinse under fresh running water (using your fingertips to massage out any remaining polish residue) and allow to dry naturally, and; (vii) while not in use, store in a dry, dust-free environment (lidded plastic storage boxes are ideal in this respect).