We Say

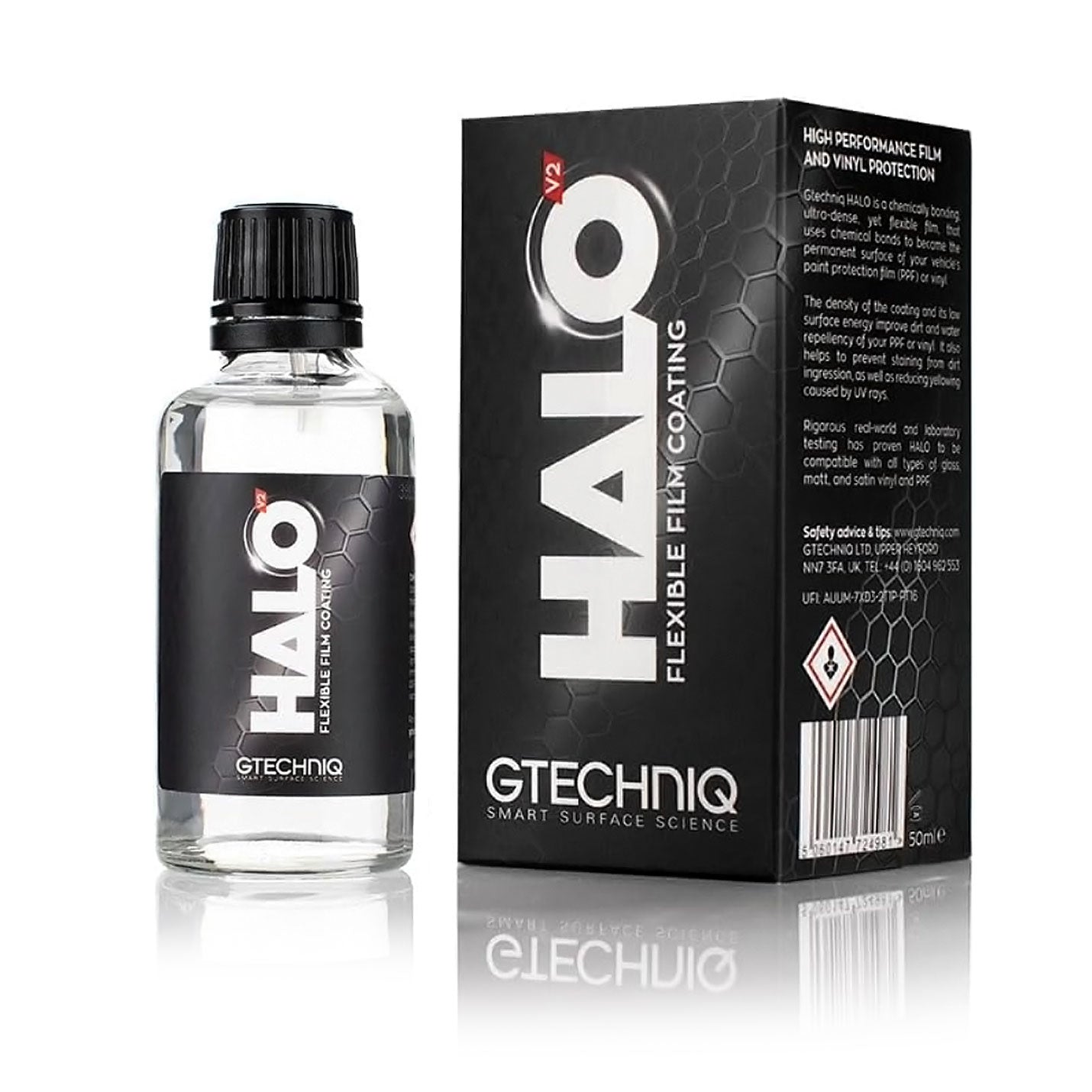

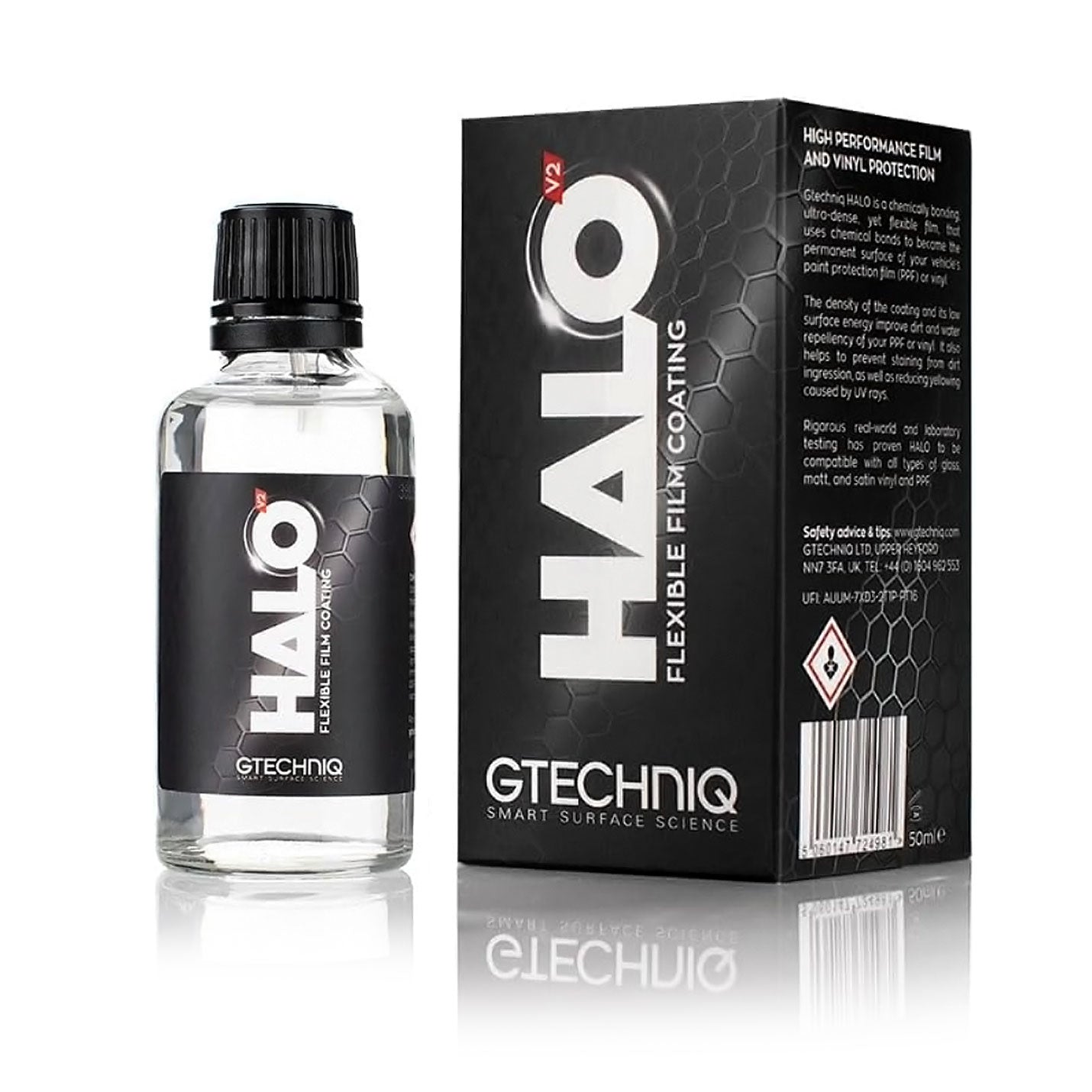

Gtechniq HALOv2 Flexible Film Coating is a scientifically advanced ceramic coating designed to protect and enhance paint protection film (PPF) and vinyl wraps. Its SiO₂ (silicon dioxide) base creates a nanoscopic molecular bond with the surface, forming a flexible yet durable barrier. This hydrophobic layer repels water and contaminants, while its UV stabilizers prevent photodegradation, protecting against yellowing, fading, and discoloration. HALOv2 also enhances the optical clarity and depth of both gloss and matte finishes, ensuring vibrant, long-lasting results.

Engineered for compatibility with self-healing films and textured surfaces, Gtechniq HALOv2 maintains the substrate's integrity while adding chemical resistance and anti-adhesive properties. Its strong intermolecular adhesion ensures the coating remains bonded, even under thermal expansion or contraction of flexible films. Ideal for automotive, marine, and architectural applications, Gtechniq HALOv2 provides a scientifically-backed solution for prolonging the lifespan and enhancing the aesthetics of PPF and vinyl surfaces.

Key Features

Beading9/10(Compared To Others)

Durability18 Months +(Average Value)

Protection9/10(Compared To Others)

Description

Gtechniq HALOv2 Flexible Film Coating is a cutting-edge ceramic coating specifically designed to protect and enhance paint protection film (PPF), vinyl wraps, and other flexible automotive finishes. This next-generation coating improves the longevity and appearance of films, offering unparalleled protection against UV rays, environmental contaminants, and dirt buildup. With HALOv2, your vehicle’s protective films maintain their clarity and finish, ensuring a sleek, vibrant look for years to come.

Features of Gtechniq HALOv2

Enhanced Durability: Gtechniq HALOv2 forms a robust, flexible barrier that adapts to the movement of PPF and vinyl, preventing cracking, peeling, or discolouration.

UV Protection: Shields films from UV degradation, reducing the risk of fading and yellowing over time.

Hydrophobic Properties: The advanced SiO2 technology provides water-repellent protection, ensuring dirt, water, and contaminants slide off effortlessly.

Self-Healing Film Compatible: Works seamlessly with self-healing PPFs, preserving their restorative properties while enhancing their performance.

UV Protection: Shields films from UV degradation, reducing the risk of fading and yellowing over time.

Hydrophobic Properties: The advanced SiO2 technology provides water-repellent protection, ensuring dirt, water, and contaminants slide off effortlessly.

Self-Healing Film Compatible: Works seamlessly with self-healing PPFs, preserving their restorative properties while enhancing their performance.

Gloss and Matte Friendly: Boosts the appearance of both gloss and matte finishes, enhancing depth and clarity without altering texture.

Box contains:

30ml or 50ml HALO Flexible Film Coating

A pair of nitrile gloves

AP2 Ultra Soft Foam Filled Applicator

Master Instruction Leaflet

Gtechniq window sticker

A pair of nitrile gloves

AP2 Ultra Soft Foam Filled Applicator

Master Instruction Leaflet

Gtechniq window sticker

Specification

| Adds Protection | Yes |

|---|---|

| Application Method | By hand only |

| Beading |

|

| Durability | 18 months + |

| Emits Strong Fumes | Yes |

| Enhances Gloss | No |

| Hardness |

|

| Layerable | Yes (allow no more than 10 minutes between coats) |

| Recommended For | Gloss, satin and matte PPF & Vinyl |

| Richness |

|

| Scratch Resistant | Yes |

| Slickness |

|

| Trim-Safe | No |

How To Use

(i) Shake bottle well and wear gloves

(iI) To apply HALO, your vehicle must be indoors and remain indoors, for at least 12 hours after the coating has been applied. For best results, good lighting is essential

(iII) If applying to previously installed film, wash and decontaminate the vehicle with Gtechniq W5 Citrus All Purpose Cleaner and W6 Iron and General Fallout Remover

(iv) Spray a 30% dilution of isopropyl alcohol (IPA) on to a Gtechniq MF1 ZeroR Microfibre Buff Cloth

(v) With your surface fully cooled, buff to remove any fingerprints or other surface contaminants. This process ensures you get the maximum number of chemical bonds between Gtechniq HALO and the film or vinyl

(vi) Apply Gtechniq HALO evenly on the application pad and set the bottle aside

(vii) Apply with applicator provided in overlapping strokes to an area roughly 2’x2′, or work to the bodylines of the vehicle

(viii) After coating a panel remove residue with an MF1 cloth. Always remove from further than you have applied, working from the outside in

(ix) Once applied carry out a final check with an Gtechniq MF1 cloth and a bright but diffused light source – this will ensure no residue remains on the surface. Allow the coating to cure for at least one hour and repeat the application process so that all film and vinyl is coated with two layers of HALO

An unopened bottle of Gtechniq HALO has a 12 month shelf life from the time of purchase

Store in a cool, dry place and use within 12 months of opening